Redefining Clean Cuts through Advanced Slag Removal

Plasma cutting is widely known for its speed and versatility, but it often leaves behind stubborn slag—hardened residue that affects the smoothness and quality of metal components. The Plasma Cutter Slag Deburring Machine is engineered to tackle this issue with precision, providing manufacturers with a high-performance solution to eliminate hard residue efficiently. This innovative system offers a powerful combination of aggressive deburring and smooth finishing, making it indispensable for industries that rely on clean, slag-free parts.

Efficient Slag Removal for Superior Component Quality

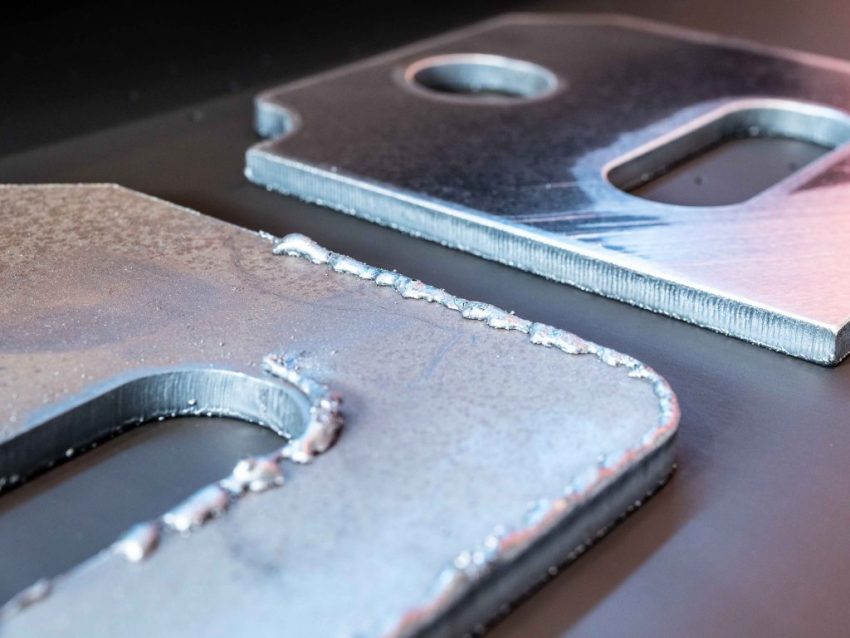

After plasma cutting, thick or uneven slag is not just a cosmetic concern—it can impact part functionality, interfere with welding or assembly, and shorten the life span of downstream tools. The Plasma Cutter Slag Deburring Machine is specifically designed to address these problems with unmatched accuracy. Using advanced abrasive belts, rotating heads, or oscillating tools, the machine targets and removes hardened slag deposits without damaging the base material.

This advanced system ensures uniform edge finishing and removes heat-affected imperfections. The result is a clean, burr-free component ready for painting, welding, or final use without additional processing steps.

Supporting High-Volume Production with Reliable Performance

Manufacturers operating in high-output environments cannot afford slow or inconsistent finishing. The Plasma Cutter Slag Deburring Machine is built to deliver reliable results in fast-paced production cycles. Whether handling thick steel plates, large sheet metal parts, or irregular profiles, this machine provides continuous operation with minimal downtime.

Its rugged build and automated settings ensure the machine maintains optimal performance over long hours. By replacing manual grinding or hammering methods, it drastically cuts labor time, reduces physical strain, and enhances workflow efficiency across the shop floor.

Trusted by Metal Fabricators Across the Globe

The Plasma Cutter Slag Deburring Machine has gained wide acceptance across industries like heavy fabrication, shipbuilding, structural steel, and trailer manufacturing. Companies trust this solution not only for its effectiveness but for its consistency in producing slag-free surfaces across a wide range of materials.

Because the machine adapts to various plate thicknesses and cutting patterns, it’s ideal for facilities with diverse fabrication needs. Its intelligent controls and adjustable settings make it possible to process everything from delicate profiles to heavy-duty plates without switching machines or compromising quality.

Intelligent Design for Precise and Safe Operation

What sets the Plasma Cutter Slag Deburring Machine apart is its combination of intelligent design and robust engineering. Modern units come equipped with intuitive touch-screen controls, programmable recipes for various materials, and real-time monitoring for performance optimization. Safety features are also built in, with enclosed systems, dust extraction, and vibration isolation for operator comfort.

This smart functionality helps teams reduce errors and standardize output, even when operated by different personnel. With user-friendly design and automated diagnostics, it ensures a safer, cleaner, and more productive working environment.

Enhancing Post-Cut Processing for Industrial Applications

The success of any cutting operation doesn’t end with a clean cut—it extends to how well the surface is prepared for the next step. The Plasma Cutter Slag Deburring Machine bridges that gap by delivering finished parts that require no secondary treatment. This seamless transition from cutting to assembly, painting, or welding enhances product quality, reduces rework, and accelerates project timelines.

In sectors where deadlines are tight and tolerances strict, this machine proves its value by maintaining output consistency and ensuring every part is free from slag-related imperfections.

Sustainability and Material Preservation in Modern Fabrication

Today’s industries aim to balance performance with environmental responsibility. The Plasma Cutter Slag Deburring Machine supports this mission by minimizing scrap and reducing the use of consumables associated with manual cleaning methods. It preserves material integrity by removing slag without excessive abrasion, keeping surfaces intact and structurally sound.

Additionally, the machine’s low-energy consumption and minimal dust generation contribute to cleaner, greener operations, aligning with modern sustainability goals.

Conclusion: A High-Impact Solution for Slag-Free Precision

The Plasma Cutter Slag Deburring Machine is more than just a finishing tool—it’s a strategic investment for manufacturers committed to quality, speed, and operational efficiency. Its ability to eliminate tough slag with precision and consistency makes it essential for any production line that values clean results and reduced labor dependency. With global trust, advanced features, and unmatched reliability, this machine stands as the definitive answer to achieving burr-free, slag-free components across all plasma cutting applications.