In today’s competitive industrial landscape, the demand for efficient, adaptable, and durable conveyor systems is higher than ever. One technology that has significantly advanced in recent years is the modular belt conveyor system, with modular belt products from Hairise taking the lead in the market. The modular belt technology is designed for flexibility, performance, and longevity, making it the preferred choice for industries ranging from food processing to automotive manufacturing. Modular belt systems offer several advantages over traditional conveyor belts, such as ease of maintenance, customization, and scalability. As the modular belt continues to evolve, it has become an essential tool in streamlining operations and improving efficiency across various sectors. The key to the dominance of modular belt products, particularly those developed by Hairise, lies in their unique design features, high adaptability, and strong performance in demanding environments. With its modular nature, the modular belt system allows for easy configuration and modification, making it the ideal solution for businesses looking to upgrade their production processes. The modular belt from Hairise is engineered to meet the varying demands of modern manufacturing, providing industries with a system that offers unparalleled performance, low maintenance, and cost-effective operation. In this article, we will delve deeper into why modular belt products, especially those from Hairise, dominate modern conveyor systems, exploring their features, benefits, and applications.

Key Features of Hairise Modular Belt Products

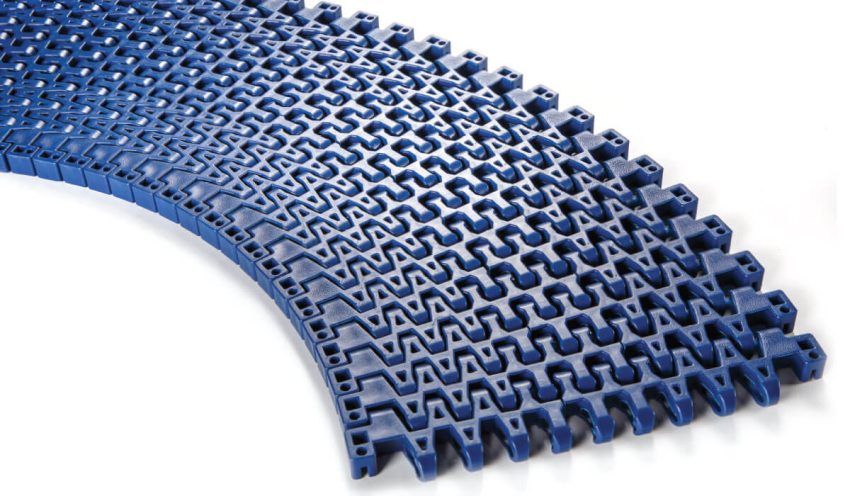

The modular belt products from Hairise offer a host of features that set them apart from conventional conveyor belts. First and foremost, the modular belt is made up of interlocking plastic modules, which provide a high level of flexibility and customization. These individual modules can be easily replaced, making maintenance significantly more convenient and less costly. Unlike traditional belts, which often require complete replacement in case of damage, the modular belt system only necessitates the replacement of the affected modules, allowing businesses to save on downtime and repair costs. Additionally, the modular belt can be easily expanded or reconfigured to accommodate changing production needs. Whether you need to change the length, width, or layout of the conveyor, the modular belt system offers the flexibility to do so without major disruptions to your operations.

Another key feature of the Hairise modular belt is its high resistance to wear and tear. Made from durable plastic materials, the modular belt can withstand harsh working conditions, including exposure to chemicals, high temperatures, and abrasive materials. This makes it an ideal solution for industries like food processing, pharmaceuticals, and automotive manufacturing, where conveyor systems need to endure heavy-duty usage. The high durability of the modular belt means that it can operate for long periods without needing frequent maintenance or replacements, making it a cost-effective investment in the long term.

Benefits of Hairise Modular Belt Conveyor Systems

The benefits of the modular belt from Hairise are numerous and contribute directly to its dominance in modern conveyor systems. One of the main advantages of modular belt technology is its ability to handle a wide range of products and materials. The modular belt can transport items of varying sizes, weights, and shapes without compromising the efficiency or reliability of the system. This versatility makes the modular belt ideal for industries that handle a diverse array of products, such as food and beverage, electronics, and packaging. The modular belt can be easily tailored to suit the specific requirements of different production lines, ensuring smooth and efficient material handling across various stages of production.

Another significant benefit of the Hairise modular belt is its energy efficiency. The modular belt system is designed to reduce energy consumption by minimizing friction between the conveyor and the transported materials. This translates to lower operational costs and a smaller carbon footprint, making it an environmentally friendly option for businesses looking to reduce their energy usage. In industries where energy efficiency is a top priority, the modular belt offers a sustainable and cost-effective solution.

Moreover, the modular belt system offers enhanced safety features that protect both workers and products. The interlocking design of the modular belt ensures that items are securely transported, reducing the risk of product spillage or misalignment. Additionally, the modular nature of the modular belt makes it easier to clean and sanitize, which is especially important in industries like food processing, where hygiene standards are critical. The easy-to-maintain design of the Hairise modular belt contributes to overall safety, minimizing downtime and ensuring that operations run smoothly without disruptions.

Applications of Hairise Modular Belt in Various Industries

The modular belt system from Hairise has a broad range of applications across different industries, each benefiting from its unique features and advantages. In the food processing industry, for example, the modular belt is used extensively for product handling, including conveying raw materials, packaging, and sorting. The modular design allows for easy cleaning and maintenance, which is crucial for meeting food safety and hygiene standards. Moreover, the modular belt can transport items with delicate surfaces, such as fruits, vegetables, or bakery products, without causing damage.

In the automotive industry, the modular belt is used for transporting heavy and bulky components through assembly lines. The durability and strength of the modular belt make it an ideal choice for moving automotive parts, including engines, chassis, and interior components. The versatility of the modular belt also allows for the system to be customized to handle different sizes and shapes of automotive components, further enhancing the efficiency of production lines.

The modular belt system is also commonly used in the electronics industry, where precision and efficiency are paramount. The ability of the modular belt to handle small, delicate components without causing damage makes it an essential part of the assembly and testing processes in electronics manufacturing. Whether it’s for moving components through SMT (Surface Mount Technology) lines or transporting finished products for packaging, the modular belt offers unparalleled performance in high-speed environments.

Why Hairise Modular Belt Products Are Cost-Effective

One of the most compelling reasons why Hairise modular belt products dominate modern conveyor systems is their cost-effectiveness. The modular belt system reduces long-term operational costs by minimizing the need for frequent replacements and repairs. Since individual modules can be easily swapped out when damaged, the modular belt reduces the overall cost of maintenance. Additionally, the system’s energy efficiency helps businesses save on electricity bills, further contributing to cost savings. The ability to adapt and reconfigure the modular belt also means that businesses don’t need to invest in entirely new conveyor systems as their production needs change, making it a highly flexible and scalable solution.

Furthermore, the durability of the Hairise modular belt system means that businesses can expect long-lasting performance with minimal downtime. This reliability results in fewer interruptions in production, ensuring that businesses can maintain high levels of productivity. The lower maintenance and repair costs associated with the modular belt system make it a smart financial investment for companies seeking to improve their operational efficiency without breaking the bank.

Conclusion

In conclusion, Hairise modular belt products have emerged as the dominant choice in modern conveyor systems due to their flexibility, durability, and cost-effectiveness. The modular belt system offers unmatched customization options, allowing businesses to tailor it to their specific needs. With its ability to handle a wide range of materials and products, the modular belt has become an essential component in industries such as food processing, automotive manufacturing, and electronics. Additionally, the modular belt provides energy efficiency, safety, and ease of maintenance, all of which contribute to lower operational costs and increased productivity. As industrial processes continue to evolve, the modular belt will undoubtedly remain a key player in shaping the future of material handling.